I’ve both seen and built quite a lot of different models of Stens. From the original Sten MkI, to the obscure Sten MkIV and the frankly weird Cornershot Mk5 I’ve built a few.

One thing I have never seen is an airsoft Sten MkIII: These were quite common in the Northern Europe campaign and were as simple as British-built Stens ever got. With the exception of the trigger group, bolt and barrel parts, these were entirely stamped steel; making them ideal for mass-production, though presented some difficulty in reproducing in my workshop as a result.

The base parts for this build came from an AGM Sten MkII, the gearbox and modified hop unit.

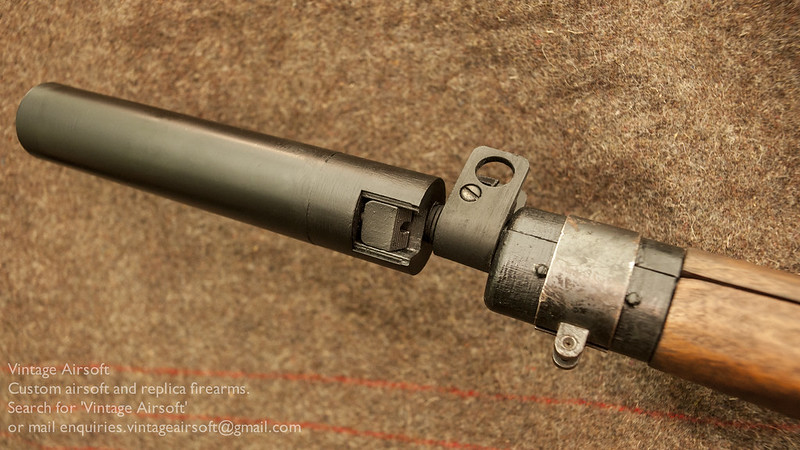

Inside the receiver the hop unit had to be turned down on the lathe to fit the narrower tube.

The top bar on the original, which holds the foresight, is a seam which is spot welded. On this build this is a separate part welded onto the tube as this is far easier to make without a press-brake.

The receiver has been made from 40mm ERW tube, I milled out the feed port, ejection port and operating handle slot. I used the original lower reciever and buttstock as these were pretty suitable already.

The back-cap is a modified MkII cap. I ground it down to give it the rounded look of the stamped piece and moved the rear sight to the front of it. I have fitted it with a flat locking screw to replicate the button on the real thing.

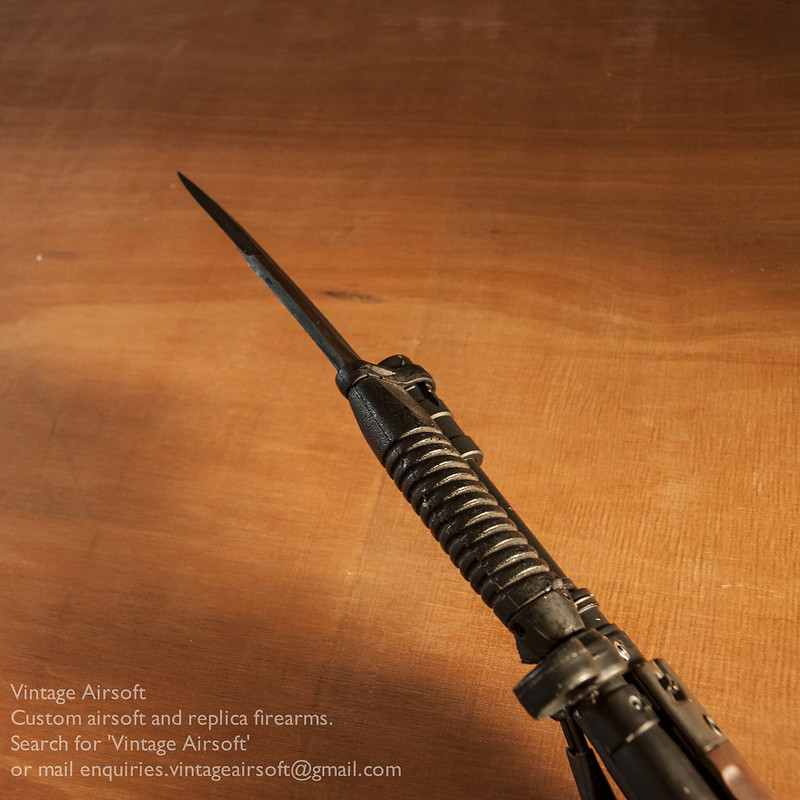

Finally, I made the front barrel bushing and cocking handle on the lathe and oil finished the other steel parts. I left most of the welds quite rough-looking to try and carry over the overall feel of the originals.

If you are interested in this build you can see the rest of the project here. If you have an idea of your own, drop us a line on enquiries.vintageairsoft@gmail.com to discuss. ‘Like’ our Facebook page or follow the blog to get regular updates on projects and interesting videos and articles.

Don’t forget you can buy VA products on the website where this will be available.