Thos of you who have followed Vintage Airsoft for some time will recognise this and be like: “Is he STILL working on that?”. Well, yes. I swear if something could go wrong on this build, it did. At least once.

So, here’s hoping this is the last build post at long last!

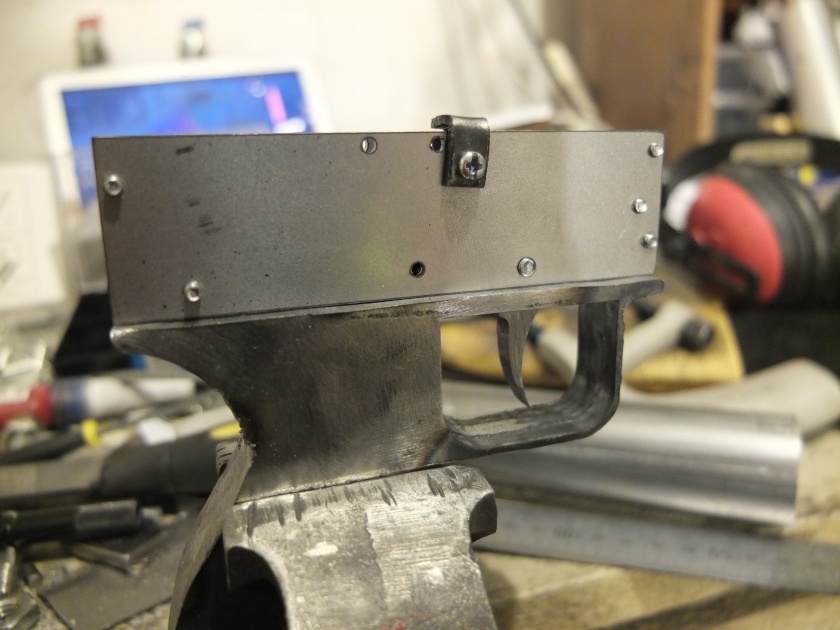

One of the problems was the air seal between the gearbox and the hop unit. This it turned out was caused by flex between these parts, resulting in variation from shot to shot.

In the end, I re-designed the mounting plate to feature a hop-up ‘vise’ to hold the unit in place really solidly. There isn’t any wobble in this sod.

I had to make a few mods to the trigger unit design and the bottom of the baseplate to work together, but now the trigger raises a sear which sets off the microswitch in the gearbox itself.

In place, clamped down! I’m still using the same feed system as before.

The feed tube comes out to meet the magazines.

Oh yes, new grips. I wasn’t happy with the old ones, one wasn’t quite spot on, but as with all things the second attempt was much better. I’ve used hardwood this time (as opposed to laminate) and cut in cross-hatching for grip.

Topping up the paintwork.

I’m really looking forward to having the finished photos on this at last.

If you are interested in this project or have an idea of your own, drop us a line on enquiries.vintageairsoft@gmail.com to discuss. ‘Like’ our Facebook page or follow the blog to get regular updates on projects and interesting videos and articles.

Don’t forget you can buy our complete products via Etsy.

The bipod itself is folded 2mm steel sheet. Designed in CAD and laser cut, I folded it by hand. I’ve never been so hot in the workshop! This was then welded to the bottom of the pivot mechanism.

The bipod itself is folded 2mm steel sheet. Designed in CAD and laser cut, I folded it by hand. I’ve never been so hot in the workshop! This was then welded to the bottom of the pivot mechanism. Woodwork is the other obvious development. Took delivery of some lovely Trend router bits that I have had my eye on for some time and set to work on the buttstock (rough cut above). Using the convex curve of a Roman Ogee bit I rounded off the faces other than the front and back.

Woodwork is the other obvious development. Took delivery of some lovely Trend router bits that I have had my eye on for some time and set to work on the buttstock (rough cut above). Using the convex curve of a Roman Ogee bit I rounded off the faces other than the front and back.

Now I just need to get the finished buttstock to match the staining job on the pistol grip covers!

Now I just need to get the finished buttstock to match the staining job on the pistol grip covers!

Close-up of the pistol grip. This shows the back where you can see the screw used to attach the trigger mechanism inside the gun.

Close-up of the pistol grip. This shows the back where you can see the screw used to attach the trigger mechanism inside the gun.