So, the New Year has come round once again. It’s time to look back at the last year’s work and forward to what’s coming in 2018!

2017’s top projects

The MG08/15 is FINALLY FINISHED! Hurrah! This thing has been the bane of my life for three years. If something could go wrong, it did go wrong. Several times.

The Sten MkIV. I’ve not shared the build for this yet as it was a quick side project. This is very fun to use and the ability to make it compact very quickly is a really nice feature.

The G43 (MkII version!). I know there is some excitement around this, although it’s not a world first by any means, I am very pleased with the end result.

The Webley snubnose was another side project, starting out life as a Well Webley this is now a useful little sidearm to tuck into my battledress for emergencies!

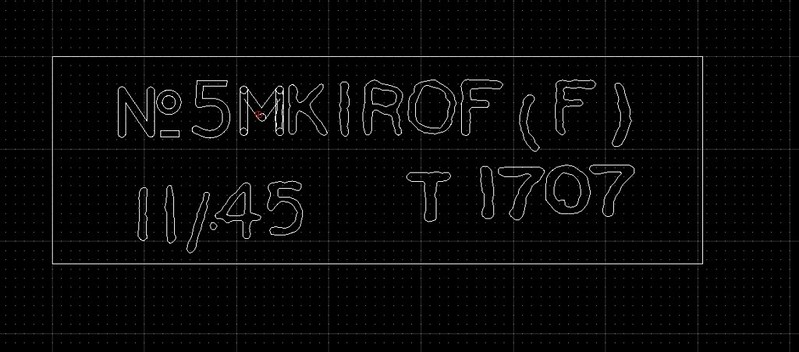

The Lee-Enfield No.5 Mk1 ‘Jungle Carbine’. A personal build, quite a few people have asked for them but no-one has committed, so I decided to make one anyway! This is my up close and personal sneaky rifle, with a custom piston and cylinder head to keep noise to a minimum. In that respect rather unlike the original…

The Pritchard-Greener bayonet has proven very popular. Its novelty value and iconic design is so appealing and I’m sure it will prove popular in Great War Airsoft circles. You can find it on the Etsy store here.

The K98k VSR conversion is a beauty (though I say so myself). This gun was for a friend of mine, I can see these being a great first conversion job for a rookie airsoft gun builder and I’ll be offering kits to help people do this.

This LMG25 is I believe a unique airsoft piece. Taking AK magazines, this was built for a contingent of Swiss Border re-enactors so you may see it on the UK show circuit this year.

I’ve done a few infantry portable artillery bits this year. I did a light version of the SMBL 2″ mortar, ideal for mid-late WWII units, this is one of the more practical mortar designs for regular skirmishing.

A more sophisticated light mortar was the M2 60mm mortar, this has full elevation and windage control to allow for very precise targeting of enemy positions.

I converted the D-Boys G98 conversion to VSR, I now use this myself with a Mancraft kit.

The FG42, probably the second most popular project, only beaten to the top spot by the G43. A lot goes into this build, the details of the folding and adjustable sights, trigger unit and bipod, not to mention the intricate hollow furniture makes this an involved process but with a very satisfying result.

The Lanchester was probably my favourite customer SMG this year, I’ve been wanting to do one for ages, and would love to see it paired with a Royal Navy Commando load out.

I’ve also expanded the range of rubber knives this year, including this NR-40, for Russian re-enactors and airsofters.

Stuff I’ve done that isn’t building guns (directly)

One of my major advances this year is building a furnace in which I can melt aluminium. The next step is to build an oven so that I can heat up and dry out my investment moulds more effectively to get production quality castings.

I got chance to play American Civil War Airsoft in the latter half of 2017, muzzle loading guns and blatting off three shots per minute is so much more fun than it sounds. I sincerely hope to see more of this in 2018.

I also jumped forward in time from my usual WWII-era equipment to something a bit more modern. My mid-1970s impressions are developing slowly, with the next major step being to sort a helmet. Then I’ll be covered for most of my Cold War impressions.

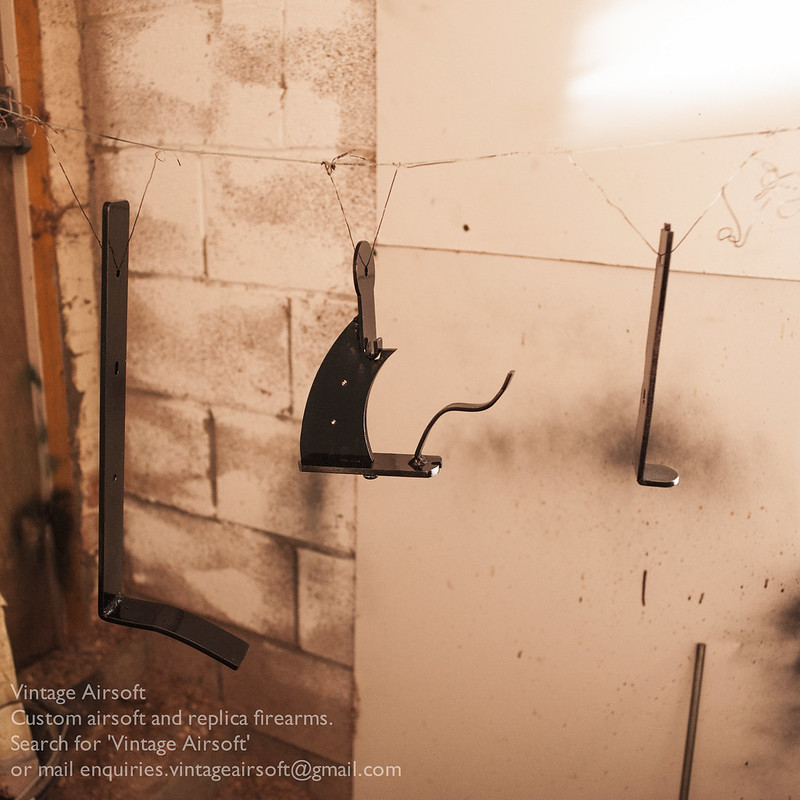

And I finally lost my rag trying to balance my webbing on normal coat hangers. I made a heavy duty, straight backed hanger so that the webbing would stay on it in the wardrobe. 20 minutes well spent preserving my sanity.

Upcoming in 2018

2018 already has some exciting projects for me. I’ve already got another unusual LMG underway, a couple of rifle builds in the works and I’m hoping to finally have the Welrod done.

I’m also hoping to have a Vintage Airsoft meet up event, once I’ve secured a site I’ll be sharing details here and over at the Facebook page.

Wishing you all a happy and interesting 2018,

Dom

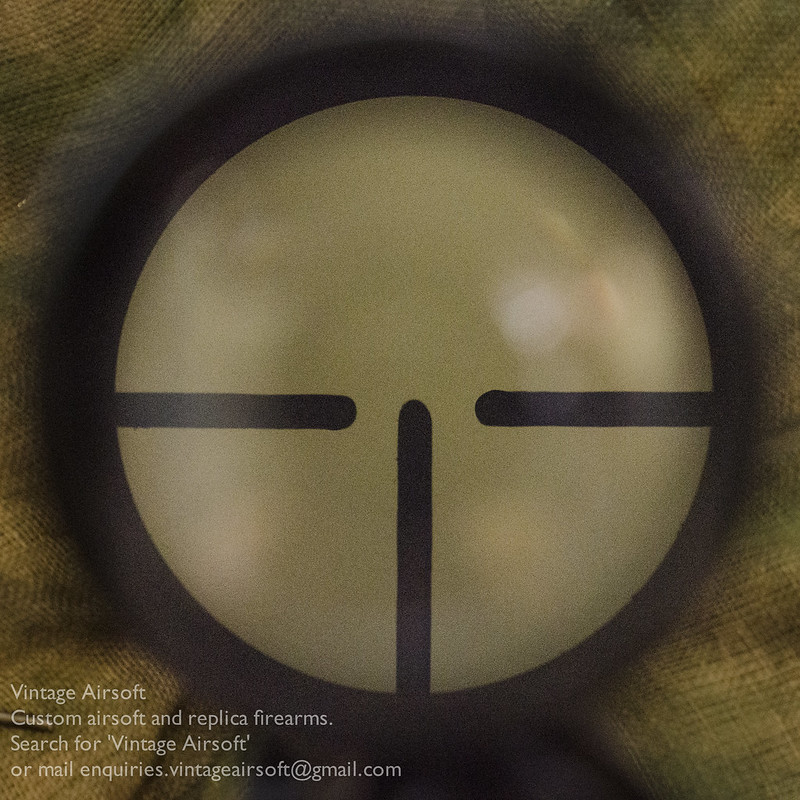

The rear sight fits in quite well, just needing a little filing down in the mountings for a snug fit.

The rear sight fits in quite well, just needing a little filing down in the mountings for a snug fit.